City Campus emitted a boisterous, afternoon-long “hiss” Nov. 10 as the first cold front of the season approached.

Echoing the feelings of many on campus, the sound was actually steam at the City Campus utility plant, released in preparation for winter weather.

“Due to the forecast, we had to start up a boiler to keep up with campus heating demands,” said Troy Webb, chief utility operator with Utility Services. “And, for safety reasons, we have to vent steam when starting up a boiler.”

While the cold, snow and ice were shocking to some, the utility plants on City and East campuses easily handled the transition, operating at around 35 percent capacity.

“The campus boiler system can handle this level of cold pretty easily,” said Scott Zwiener, a plant operator with Utilities Services. “On the really cold days, we only operate at about 65 percent capacity.

“Really, one boiler could have handled demand today. But it’s good to have that redundancy in place in case something happens.”

UNL’s heating system is built to handle greater demands, but operating levels are kept below maximums to decrease wear and tear. For example, the largest boilers in the UNL utility system generate 80,000 pounds of steam per hour, but will run at no more than 65,000 pounds per hour, Zwiener said.

Utilities Services employees staff the City and East campus plants 24 hours a day, seven days a week, 365 days a year. The City Campus plant is also responsible for monitoring the new Centralized Renewable Energy System at Nebraska Innovation Campus.

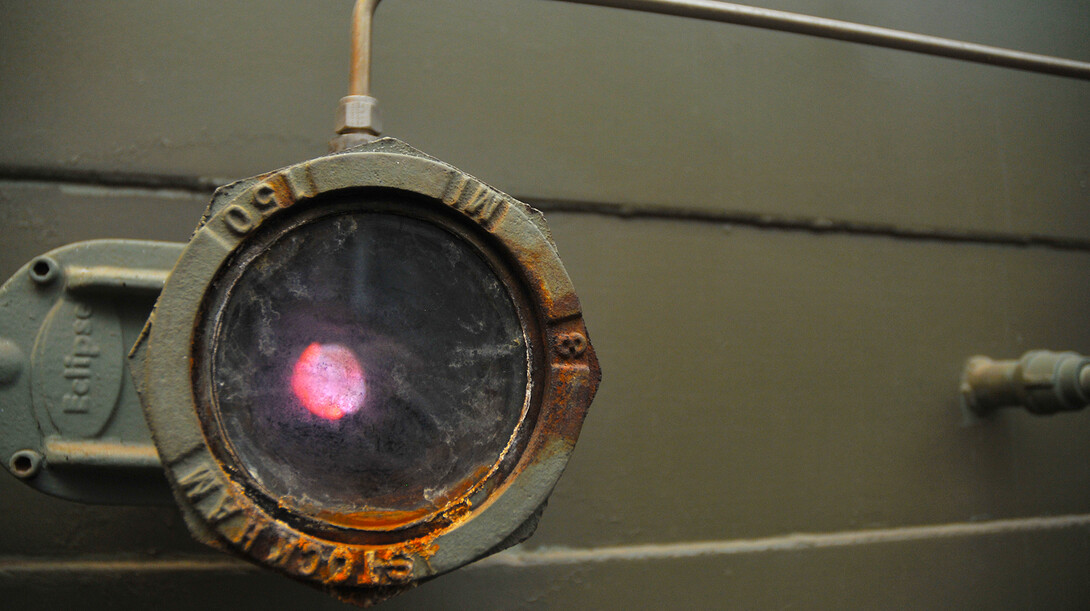

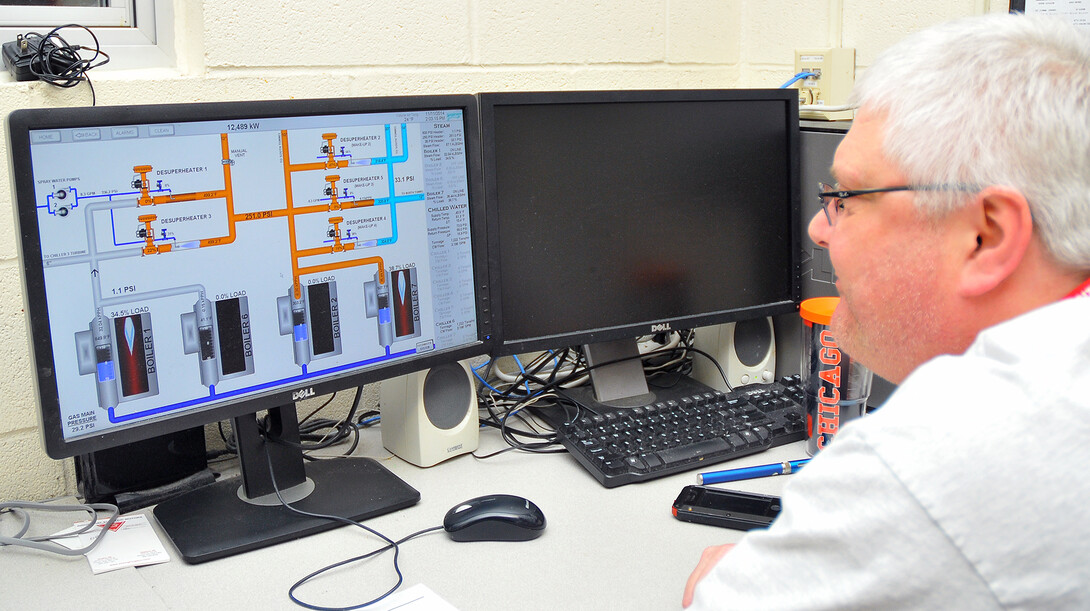

The workers monitor UNL’s heating and cooling systems from control rooms at both campus plants. Every hour, with the multistory steam generators vibrating the facility, throwing off heat and noise, employees log operation levels by hand at monitoring stations alongside the boilers.

“The heat is nice when it’s cold out, but, after almost 18 years, I don’t even notice the noise,” Zwiener said. “Actually, this is one of those jobs that no one really notices until the heat or air conditioning goes out. Then people get to know you pretty quick.”

In truth, the campus utility plants work harder during the summer than winter, said Rhett Zeplin, assistant director with Utility Services.

“During the summer months, we are cranking pretty hard to keep up with chilled water demands for air conditioning,” Zeplin said. “The system can handle demand, but it works a lot harder when cooling is needed.”

While the system may work less in the winter, heating is more expensive than cooling, said Kirk Conger, energy projects manager with Building Systems Maintenance.

“It actually costs two to three times as much to heat a cubic foot of air one degree than it does to cool it,” Conger said.

Employees can help reduce UNL’s winter utility costs by:

• Setting thermostats to a comfortable level and leaving them alone. UNL’s energy management and control system allows most room temperatures to dip overnight and on weekends to automatically save energy.

• When out of offices for an extended period of days or weeks in the winter, set the thermostat to 65 degrees.

• Close and lock windows. Close curtains and blinds overnight.

• If a room is too warm, notify building maintenance reporters rather than opening a window.

• Turn off lights, computers and other appliances when leaving for the day. Lights should be turned off anytime you will be out of the office for more than a few minutes.

• Always keep the lab hood sash closed when not actively loading or unloading a hood. Turn off unnecessary exhaust fans.

• Notify the BMR to report equipment or rooms that are not functioning properly, or other areas of energy waste. Any room that is 68 degrees or warmer will not be treated as a cold room.

For more information on building energy use guidelines, click here.

UNL also offers information on energy use in each building. The totals are updated monthly.

“UNL is not in crisis mode in terms of having to reduce energy costs to meet budget demands,” Conger said. “But it’s wise for faculty, staff and students to use energy in an efficient way.”