The University of Nebraska–Lincoln will begin to fill and test a new specialized water tank that is designed to reduce energy costs and increase heating and cooling system efficiency.

The 8.1-million-gallon tank, which is scheduled to go online in spring 2018, will work like a battery, holding chilled water in reserve to cool campus buildings during peak demand periods. The system reduces energy costs by chilling stored water when energy use on campus is low, primarily at night and on weekends.

"The thermal energy storage tank allows us to shift the energy used to chill water away from peak-demand periods during the day to lower-demand times at night and on weekends," said Stefan Newbold, assistant director and engineering manager for facilities planning and construction. "That shift helps flatten the university's electric load profile, eliminating sharp increases in energy used and resulting in money savings."

Energy cost savings for the $11.9 million City Campus tank are estimated to be between $850,000 and $900,000 annually. A smaller, 2.8-million-gallon tank in use since 2012 on East Campus has recorded yearly energy cost savings of approximately $350,000.

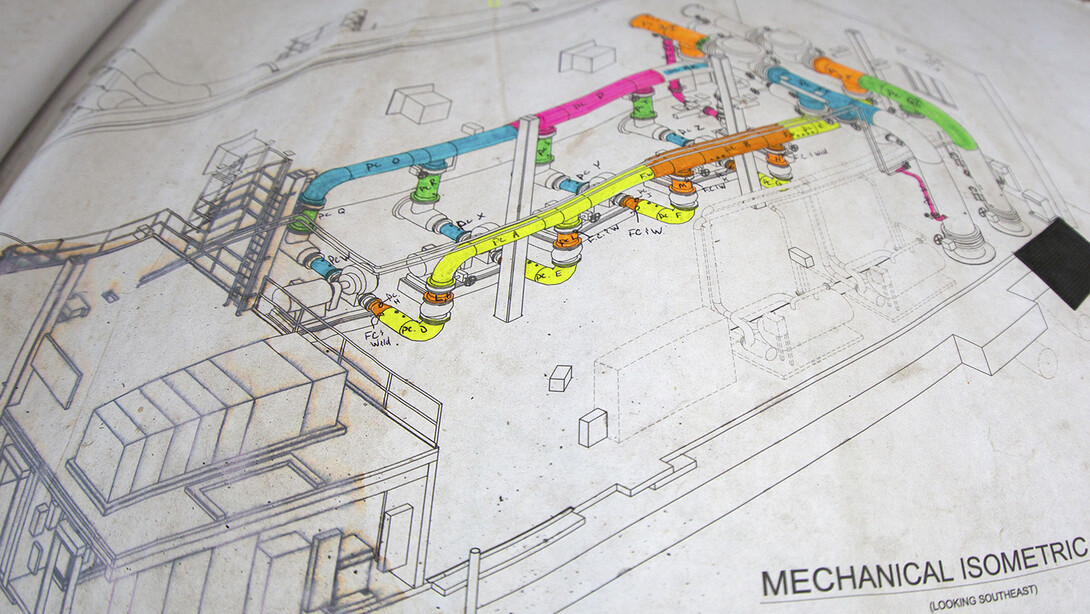

The new tank is located immediately north of the landscape services building near 17th and Y streets. Construction started in November 2016 and will be substantially completed this fall. Earlier this summer, an underground bore project connected 36-inch specialized pipe from the tank to the campus chilled water system. The bore successfully installed two 630-foot-long stretches of pipe under Antelope Parkway, linking to the campus system near 16th and W streets.

Starting the week of July 24, workers will begin to fill the tank with water and test it for leaks. Charlie Griesen, construction coordinator for Facilities Management and Planning’s Utility Services, said the filling and testing is scheduled to last about two weeks.

Construction continues on the support building immediately west of the tank.

Tank capacity can supply chilled water to City Campus for six to eight hours during peak demand periods. The tank will be full automated and controlled remotely from the City Campus Utility Plant near 14th and W streets.

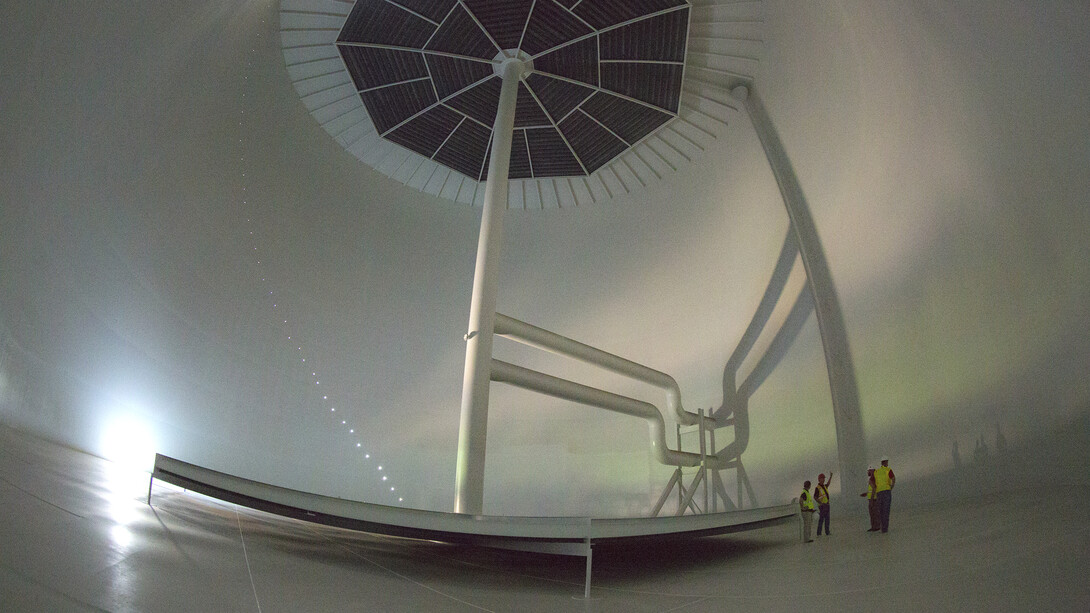

The tank itself is made of welded plate steel, which will be skinned by a three-inch-thick layer of insulation covered by decorative aluminum paneling. A retention pond designed to handle storm water runoff from the top of the tank is also being integrated into the site.

The tank is nearly 100 feet tall with a diameter of 120 feet.

When complete, the tank will provide electrical demand savings, expand redundancy to meet the university’s cooling needs and reduce wear and tear on existing chillers. The City Campus tank, which could provide air conditioning to approximately 1,600 average-sized homes, is also designed to supply chilled water to future university facilities built on the east side of Salt Creek.