Rain, sleet and snow can take the shine off an emerging form of solar cell, but University of Nebraska-Lincoln engineers have devised a way to help keep it from going dead in the water.

Perovskite – a class of materials with a signature atomic structure – has become a darling of the solar industry and the focus of much research over the past several years. Besides featuring many properties essential to an efficient solar cell, perovskite can be produced more easily and cheaply than silicon, the current industry standard.

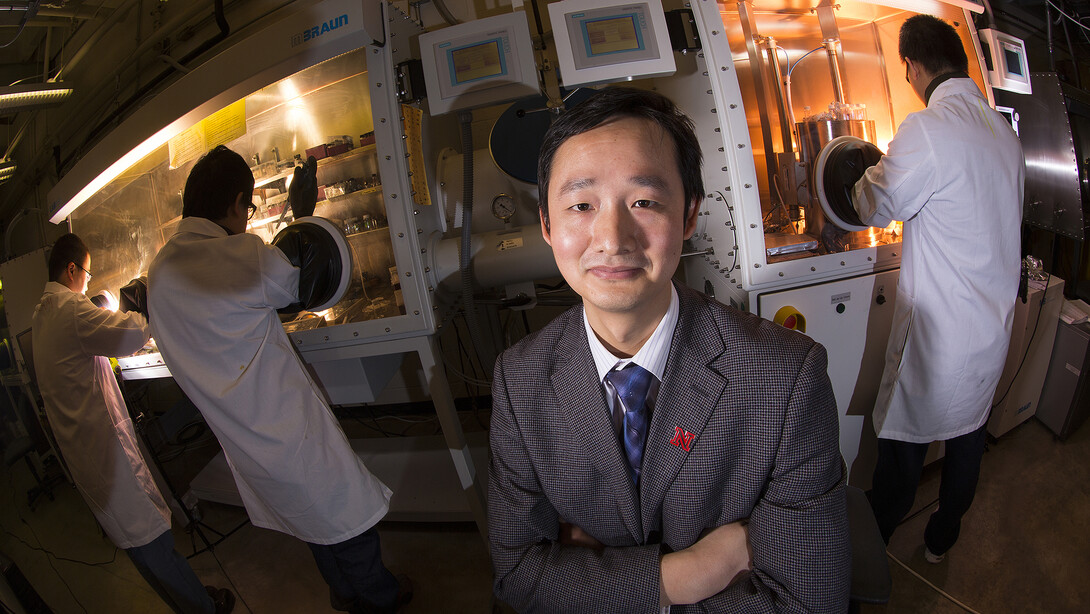

Yet the material also slurps up moisture about as readily as salt, rendering it unstable and limiting its lifespan in the sometimes harsh weather that many solar cells must endure. In response, a research team led by Jinsong Huang has detailed an approach that can buffer perovskite against moisture without sapping its ability to convert sunlight into electricity.

As reported in the journal Nature Communications, the team’s method allowed a perovskite cell to maintain nearly 90 percent of its efficiency after a month of exposure to high humidity and periodic submersion in water. It represents the latest of many milestones in Huang’s quest to make perovskite-based solar technology more affordable and efficient.

“Once the material absorbs moisture, it dies very fast,” said Huang, a Susan J. Rosowski Professor of mechanical and materials engineering. “In some cases, people can see it (happen) in several hours.

“Manufacturers want to know whether this material is stable or not. We talk about giving them a lifetime of about 25 years on a roof. It’s really time to address this issue.”

To do so, Huang and his colleagues overlaid perovskite with a protective layer of cage-like molecules formed by collections of 60 carbon atoms. Using silane molecules as a bridge, they also connected this layer with water-repelling molecular tails that consist of one carbon and three fluorine atoms.

Collectively, the approach made the perovskite substantially more resistant to moisture. But like many other methods designed to buffer perovskite, it also reduced the material’s conductivity and, by extension, its efficiency at turning sunlight into usable power.

“We do not want to compromise efficiency when we gain stability,” Huang said. “We want both.”

So the team mixed its carbon-based layer with a compound called methylammonium iodide, finding that this boosted the depleted conductivity by more than 100 times. The combination ultimately yielded an efficiency of 19.5 percent, just a couple of percentage points lower than the best-performing perovskite hybrids have achieved under ideal conditions.

“The whole world is working on this, because everyone knows the challenge,” Huang said. “I think the effectiveness of this method, in terms of (extending) the perovskite’s lifetime, should be among the best.”

Huang authored the study with postdoctoral researchers Yang Bai, Qingfeng Dong, Liang Shen and Wei Wei, alongside doctoral students Yuchuan Shao, Yehao Deng, Qi Wang and Dong Wang. The team received support from the U.S. Department of Energy and the Office of Naval Research.