Researchers at UNL have developed permanent magnet materials through a new process of growing and assembling nanoscale magnetic clusters.

The technique relies on the fabrication of nanoclusters as building blocks with unusual crystal structures and outstanding magnetic properties. The system enables the synthesis of particles under 10 nanometers in size, which can be co-deposited with atoms forming a second phase with properties that complement those of the nanocluster phase.

The technique was published in a study last week in Advanced Materials, and is featured as a frontispiece reserved for highlighting outstanding communications.

These new ways of creating magnetic materials are important because until now, the best magnetic materials for permanent magnets have been compounds containing rare-earth elements such as neodymium or samarium, but these materials have become scarce and expensive because of the so-called “rare-earth” crisis.

“Because of the widespread use of magnetic materials in energy-related applications such as hybrid cars and wind turbines, the development of a replacement material could be a game-changer,” said Balamurugan Balasubramanian.

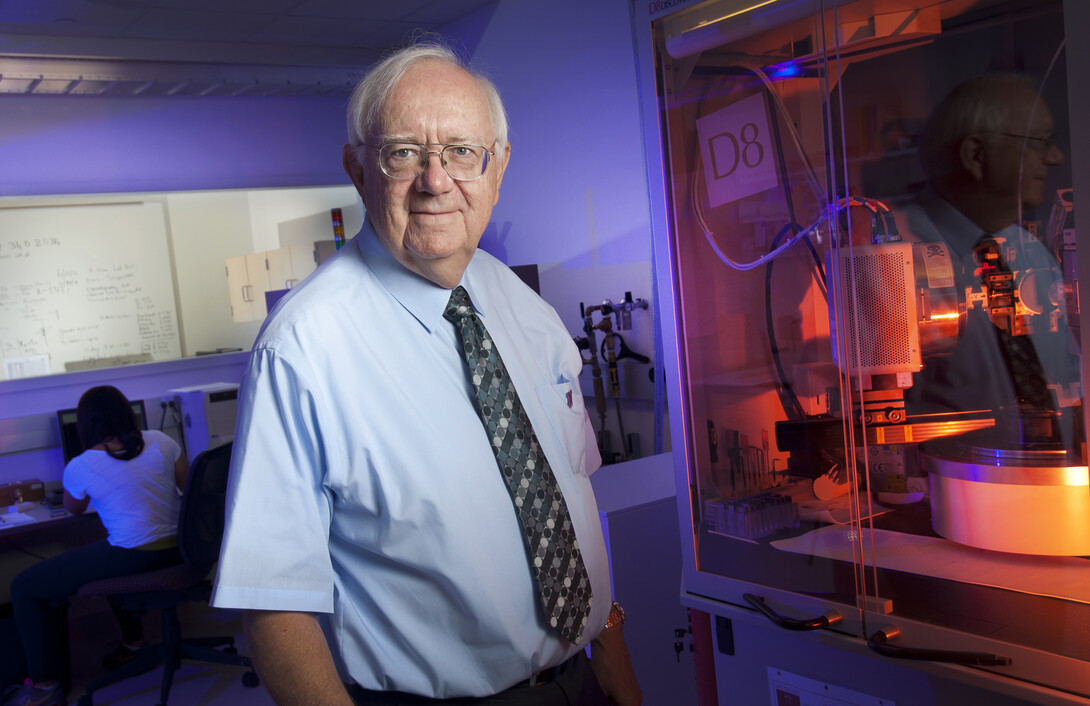

Balasubramanian, a post-doctorate postdoctoral research associate in the Nebraska Center for Materials and Nanoscience, is the lead author on the study. He was assisted by co-authors are David Sellmyer, George Holmes University professor of physics and director of the center; graduate student Bhaskar Das; Wenyong Zhang, post-doctorate postdoctoral research associate; and Ralph Skomski, research professor in the center.

While this breakthrough shows promise, Sellmyer noted that “this result is based on a model system and further research will be required to develop methods for making bulk materials suitable for several applications.”

The study was supported by the U.S. Department of Energy, the National Science Foundation, and was performed in the Nebraska Center for Materials and Nanoscience, which is supported by the Nebraska Research Initiative.