Virtual Incision, a medical device company founded by University of Nebraska faculty, has relocated and expanded its headquarters at Nebraska Innovation Campus.

In November, the company launched by University of Nebraska-Lincoln engineer Shane Farritor and University of Nebraska Medical Center surgeon Dmitry Oleynikov moved into a new space on the first floor of the Rise Building, NIC’s new three-story, 75,000-square-foot structure. Virtual Incision’s space has four main areas: a manufacturing facility, a research and development laboratory, a mock operating room and office space.

These facilities house an operation that’s the first of its kind in Nebraska, integrating research and development, quality control, assembly and test procedures.

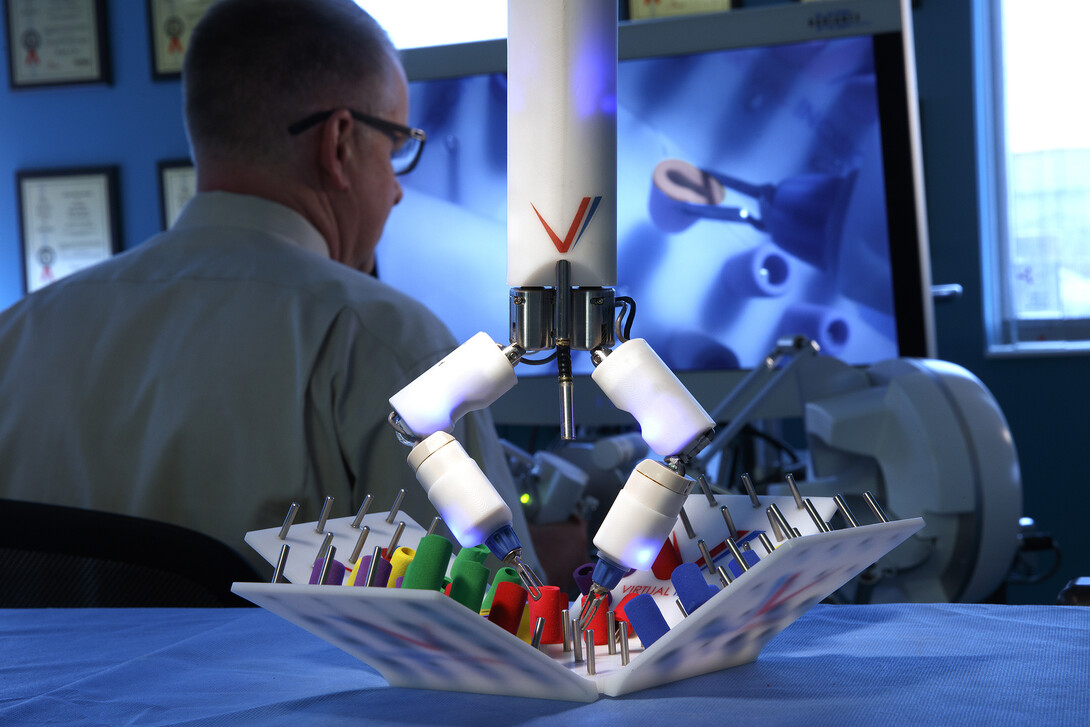

The move enables Virtual Incision to expand and advance its work on a next-generation, miniaturized surgical robot designed to minimize the recovery time and costs associated with abdominal surgeries, particularly colon resections. That procedure is used to treat patients with lower gastrointestinal diseases like diverticulitis, Crohn’s disease, inflammatory bowel disease and colon cancer.

The company is currently preparing the robot for human trials and consideration for commercial approval by the U.S. Food and Drug Administration.

Farritor said progressing to the next phase of commercial development motivated the company’s decision to move out of its original NIC office, which opened in 2016. In addition, the company is growing in size, with several new employees and medical device consultants joining Farritor, Oleynikov and John Murphy, Virtual Incision’s chief executive officer, in the past year.

“We needed to create a new manufacturing and prototyping facility,” said Farritor, Lederer Professor of Engineering and Virtual Incision’s chief technology officer. “We’re delighted to be able to do that here in Lincoln in a new, first-rate building.”

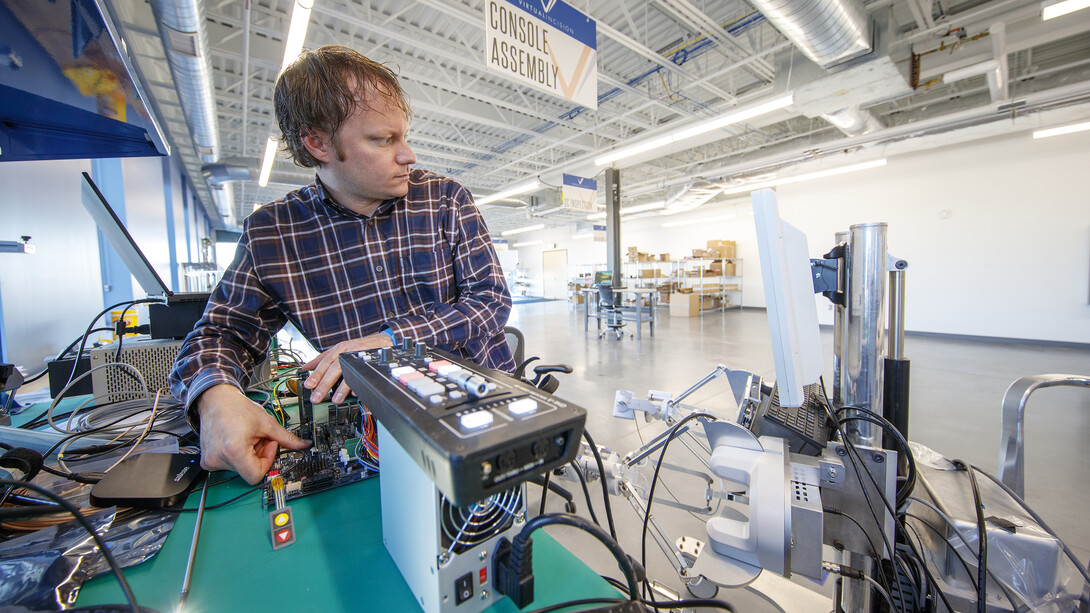

The manufacturing space — the largest of the four sections — allows the company to keep a close eye on producing high-quality robots, cameras, consoles and surgical tools. This quality control is key for devices used in human surgeries, Farritor said.

“When you produce medical devices, you have to maintain strict and regulated manufacturing best practices,” Farritor said. “We’ve never had this capability before.”

The facility enables Virtual Incision to produce its system for colon resection surgery, as well as follow-on mini robots for a broad range of abdominal procedures, such as gallbladder removal and hernia repair.

The new headquarters also includes a mock operating room, providing a realistic environment for testing, training and demonstration purposes. Prior to the move, bench work, usability and preclinical testing, and the training of new surgeons to use the device took place at UNMC. Now, some of that work will happen at NIC.

Farritor said the company is happy to have a larger facility with expanded capabilities, while remaining at NIC. Retaining close proximity to Nebraska Innovation Studio, NIC’s creative hub where makers and builders collaborate to conceptualize and execute projects, is another bonus.

“We love being near the studio,” he said. “We often use the equipment there to make quick prototypes.”

The move marks another forward stride for Virtual Incision, whose momentum has been building rapidly in the last few years. In 2017, it announced it had raised $18 million in equity funding for the miniaturized robot. In 2016, the device became the first miniaturized robot to carry out complicated surgical tasks inside a living human. Also that year, NUtech Ventures, the university’s intellectual property and technology commercialization unit, named Virtual Incision the Startup Company of the Year.

NIC’s $15.3 million Rise Building opened in November 2018, creating more space after the public-private research campus’ first 380,000 square feet reached full capacity. The building, located at 2125 Transformation Drive, is modeled on tech company headquarters in San Francisco and Montreal. It includes a space called The Hub, an area that features furnished offices of various sizes, collaboration spaces, a shared breakroom and a shared conference room.